In the field of fast-paced automobile manufacturing, the demand for high-quality and durable air filters continues to increase. By preventing dust, debris and pollutants from entering the engine, these filters play a vital role in protecting engine performance, improving fuel efficiency and prolonging vehicle life. The core of the production of high efficiency air filter is a key equipment: plate air filter rotating paper folding machines. However, how does this special equipment change your production line, what is the difference between it and traditional tools, and how can it give full play to its potential to meet growing market demands? In this comprehensive guide, we’ll answer these questions and more-to explore the core functions, unique advantages, product specifications and practical applications of this innovative equipment, while emphasizing the key role of reliable origami machines and origami equipment in the success of modern manufacturing.

1. Define rotary pleating paper machine with plate air filter and its core concepts.

Before going into the details, let’s clarify some key definitions, so as to set the foundation for understanding how this equipment can improve efficiency.

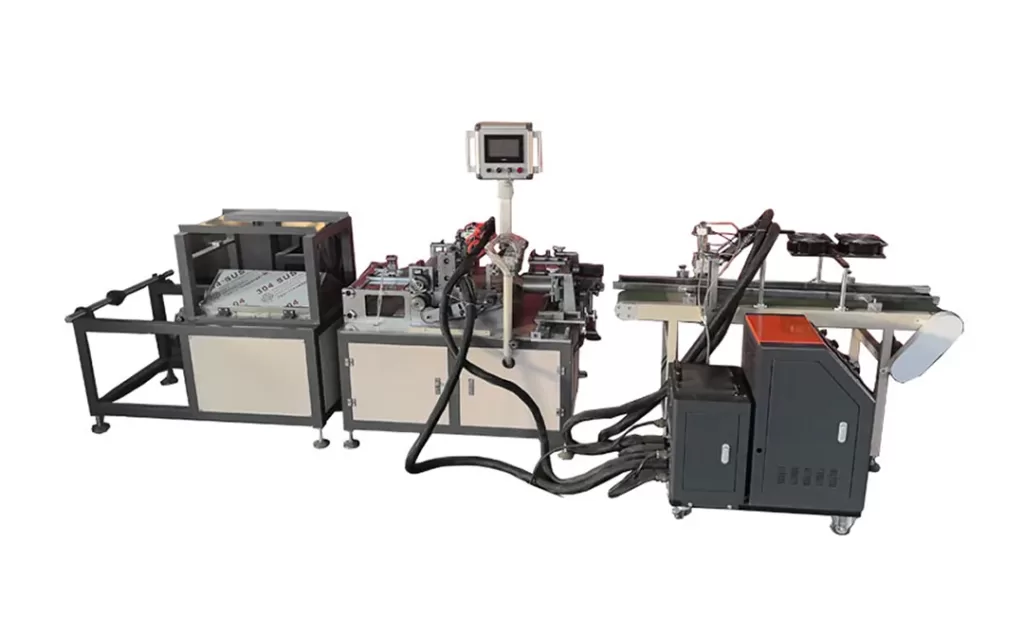

Plate air filter rotary pleating paper machine: a special industrial equipment, which is used to fold filter paper into accurate and uniform pleats to produce air filter components for automobiles. It integrates the processes of humidification, tension control, bonding and folding to create a folded filter media, maximize the surface area, and improve the filtration efficiency and production.

Folding machine: a large class of equipment used to fold paper or paper-based materials into specific shapes or structure. In the filter production, a paper folding machine refers to the equipment tailored for filter media, which can ensure the consistent pleat height, spacing and durability, and directly affect the production speed and product quality.

Paper Folding Machinery: An umbrella term encompassing all mechanical systems, components, and accessories used for folding paper in industrial settings. High-quality paper folding machine gives priority to accuracy, speed and compatibility with different paper types, which are the key factors to simplify the workflow of filter manufacturing.

Paper Folding Equipment: the individual tools, modules, or attachments that make up a complete folding system. This includes pleating rollers, tension shafts, gluing device and conveyor belts, all of which work together to provide a reliable and repeatable folding effect, which is essential for expanding the production scale without affecting the consistency.

A study by MarketsandMarkets (https://www.marketsandmarkets.com/Market-Reports/automotive-air-filter-market-1150.html) notes that 78% of filter manufacturers cite “production efficiency” and “pleat precision” as the top factors influencing their choice of paper folding machinery—proving that the right equipment directly correlates with market competitiveness.

2. How Does the Panel Air Filter Rotary Pleating Paper Machine Work? Step-by-Step Process

In order to understand how this kind of paper folding machine improves efficiency, let’s break down its simplified and automated workflow-aiming at minimizing manual intervention and maximize output.

(1). Material Preparation: put the cut filter paper (customized to the required width) on the shelf. The working width of the machine is 50-320 mm, which can adapt to various filter sizes for different models, without multiple special machines.

(2). Humidification-tension control: the filter paper softens the material through a steam humidification system (2.5 kw power) to prevent cracking during folding and reducing waste. Then, it moves to a tension axis platform, which maintains consistent pressure to ensure the smooth paper feeding, which is a basic feature of the design of high-performance folding machine, and can avoid paper jams and production delay.

(3). Roll Marking: the humidified and tension-controlled paper enters the roll marking shafts, and the roll marking shaft produces accurate creases to guide the folding process. This step can ensure that the pleat spacing is consistent, which is the key factor in filtration efficiency and product consistency, and also the key to reducing rework and customer returns.

(4). Hot Melt Gluing: Hot melt glue is applied to both ends of the filter paper via a 10 Kg gluing device with 2 glue outlet hoses. Glue holds the folds in place, preventing them from spreading and ensuring long-term durability, while automatic application eliminates the common uneven adhesion in manual processes.

(5). Rotary Pleating: the paper is fed into a collecting wheel that performs the rotary pleating action. The core component of this origami machine can fold the paper into square, trapezoid or polygon, thus adapting to different filter design requirements, without time-consuming tool replacement.

(6). Glue curing: the folded filter paper is moved to the conveyor belt, and the hot melt adhesive is cured on the conveyor belt, locking the folds in the final shape. This continuous workflow ensures non-stop production, with no need for manual drying or curing steps.

3. Key Specifications: Why This Paper Folding Equipment Stands Out for Efficiency.

The panel air filter rotary paper folding machines is engineered for performance, with specifications that directly address the need for faster, more reliable production. The following are key technical details that make it a game changer.

| Specification | details efficiency advantages |

| Working width | 50-320 mm (suitable for small to large filter sizes), which reduces the need for multiple machines; Handling different orders |

| Folding height | 12-75 mm (which can be adjusted according to different pleat depths), and the customized filters can be quickly adjusted; No rearming downtime. |

| Production speed | 5-70 m/min (high-speed operation for large-scale production), and compared to semi-automatic tools, the output doubles; Meets pressing deadlines |

| Motor Power | 3 kw (energy-efficient yet powerful performance) Lowers operational costs; Reduce the waste of energy in long-distance running. |

| Humidifying power | 2.5 kW (to ensure the best paper softening but not over saturation), so as to minimize the paper waste caused by breakage; Maintain a stable quality |

| Machine Size | 3300*850*1350 mm (compact design, improving the efficiency of the factory floor) to save space; Suitable for the existing production lines, without major modification. |

| Weight | 1200 kg (firm structure, stable at high speed), reducing the downtime caused by machine vibrations; Extend the service life of equipment |

| Hot gluing device | 10 kg gluing quantity, with 2 glue outlet hoses, continuous gluing, without frequent replenishment; Uniformly applied |

| Intuitive programming of PLC brand | SJ (Reliable Control System for Automatic Operation); And the training time for operators is reduced. |

| Origin | Hebei, China (manufactured according to international quality standards) is durable; Minimize maintenance related downtime. |

| warranty | 1-year (comprehensive guarantee, so that you can sit back and relax) to prevent unexpected failures; Ensure the consistency of production |

| Packaging | shrink film+wooden cases (safe transportation and storage) for safe delivery; Broken equipment will not cause delay. |

These specifications make this machine a multi-functional and high-performance paper folding machine, which can balance speed, accuracy and durability, which is the key requirements for modern filter manufacturers seeking high efficiency and scale.

4. Unique Advantages: How This Paper Folding Machinery Boosts Production Efficiency.

When it comes to efficiency, what is the difference between this paper folding machine and the traditional folding equipment? The following is its outstanding advantages.

Servo motor precision: Equipped with servo motors, the machine provides high-precision control over pleat spacing, height and shape. This can ensure consistent filter quality, reducing waste (a major efficiency killer) and improve the reliability of products. Different from ordinary paper folding equipment, the latter may be difficult to maintain accuracy at high speeds, and the servo drive technology can maintain accuracy even at the speed of 70 meters/minute, without post-production inspections and rework.

High-speed continuous Production: the speed range is 5-70 m/min. Compared with manual or semi-automatic folding methods, the production capacity of this machine is doubled. This makes it ideal choice for large-scale manufacturing, helping enterprises to meet the urgent deadlines and growing market demand without hiring extra employees.

Flexible Compatibility: the machine supports square, trapezoidal, and polygonal pleat shapes, adapting to the diverse needs of automotive air filters for sedans, passenger cars, SUVs, sports cars, and other vehicle models. This flexibility eliminates the need for multiple dedicated machines, and reduces production costs, floor space and switching time between orders.

Eco-Friendly Output: Designed to produce environmentally friendly oil filter elements and air filters, the machine aligns with global sustainability trends while improving efficiency. Non-toxic and biodegradable adhesive is used in the hot melt bonding process, and the efficient folding process minimizes the waste of paper, thus reducing the material costs and reducing the impact on the environment.

User-Friendly Automation: Controlled by an SJ PLC system, the machine offers intuitive operation with minimal manual intervention. Operators can easily adjust settings (pleat height, speed and glue application) through the digital interface, thus reducing training time and human error, the two main reasons for production delay.

5. Main Application Scenarios: Where This Paper Folding Equipment Excels.

The rotary paper folding machines with plate air filter is specially designed for automobile industry, covering all kinds of vehicle and maintaining high efficiency.

Sedans & Passenger Cars: the machine produces compact, high-efficiency air filters that fit tight engine compartments. Its uniform pleats maximize the filtration surface area, and at the same time, the high-speed production meets the mass demands of mainstream automobile manufacturers.

SUVs & Crossovers: These vehicles often operate in off-road or dusty conditions, requiring durable air filters with deeper pleats. The adjustable folding height (12-75 mm) and sturdy structure of this machine enable it to effectively produce sturdy filters, even if it is a special orders.

Sports cars: High-performance sports cars needs an air filters that balances filtration efficiency and airflow. The precise pleating of the machine ensures the minimum air resistance while capturing tiny pollutants-all production speeds are consistent with the production speed of low-volume, high-value sports car.

Commercial vehicles: Although it is mainly concentrated in passenger cars, the working width of this machine is wide (up to 320 mm), which enables it to produce filters for light commercial vehicles (trucks and pickup trucks) without sacrificing efficiency. This versatility helps manufacturers to expand their product lines without investing in new equipment.

In addition to automotive applications, the paper folding machines can also be used to produce air filters for industrial equipment, HVAC systems and other industries, thus expanding its uses and providing manufacturers with additional sources of income.

6. Frequently asked questions

Q 1: How much time can this machine save than manual folding?

A 1: On average, compared to manual or semi-automatic methods, the production time of this machine can be shortened by 50-70. For example, a batch of 1,000 filters that takes 8 hours to produce manually can be completed in 2-3 hours with this machine—freeing up staff for other tasks.

Q 2: What types of filter paper are compatible with? Does switching the type of paper affect efficiency?

A 2: the machine works with most standard filter papers (cellulose, synthetic, hybrid) and accommodates thicknesses from 0.1 mm to 0.5 mm. Switching paper types takes less than 10 minutes, with no impact on production speed—ensuring efficiency even for mixed-material orders.

Q 3: How often does the machine need to be maintained, will it affect the normal running time?

A 3: Regular maintenance (lubricating and cleaning the gluing device) only takes 1-2 hours a week, which can be arranged at off-peak hours. The machine’s durable construction and 1-year warranty minimize unexpected breakdowns, ensuring uptime rates of over 95%.

Q 4: Can the machine be integrated into existing production lines, or do you need new settings?

A 4: the compact size (33008501350mm) and flexible design of this machine enable it to be seamlessly integrated into most existing production lines. It requires standard electrical connections and the smallest floor space, shortening the installation time to 1-2 days.

Q 5: What is the return on investment in this paper folding machine?

A 5: Most manufacturers will see a return on investment within 6-12 months. This machine reduces labor costs (fewer operators are needed), material waste (precise folding minimizes paper scrap) and downtime (automatic operation eliminates human error delay), and at the same time improves the output and can be extended to new markets.

Sum up

The panel air filter rotary pleating paper machine is more than just a paper folding machine—it’s a strategic investment in production efficiency, quality, and scalability. By automating key processes, providing accurate results and adapting to different customer ‘needs, it helps auto filter manufacturers to stay ahead in the highly competitive market. Whether you’re a small-scale producer looking to increase output or a large enterprise aiming to streamline workflows, this paper folding equipment offers the performance, reliability, and versatility needed to enhance productivity and profitability.