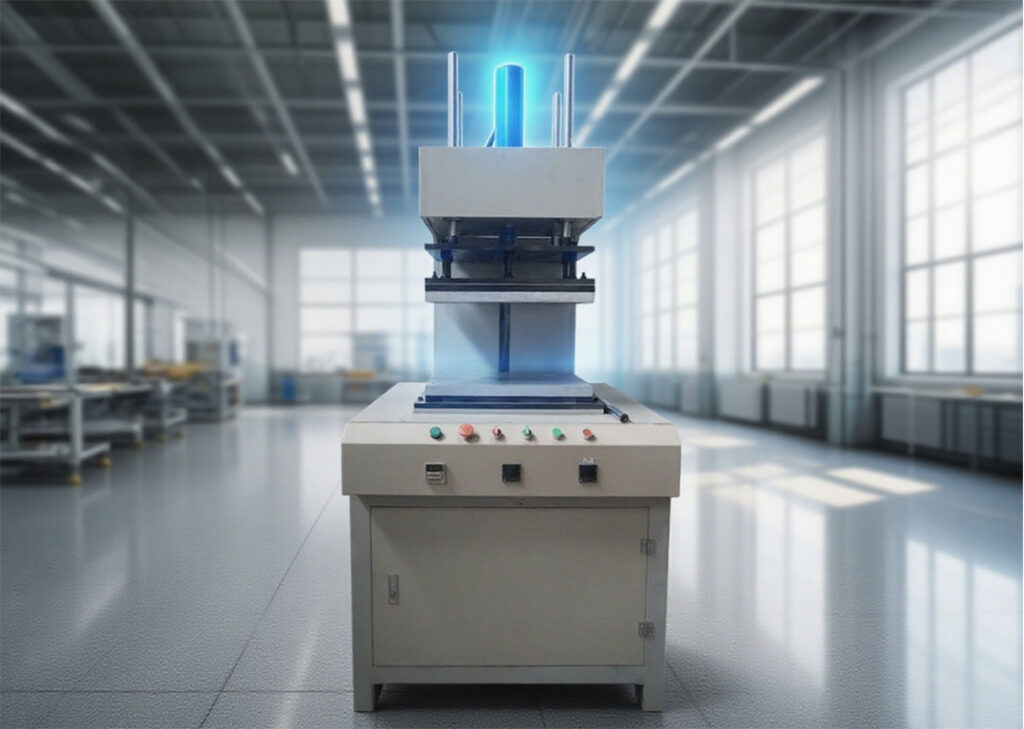

In the competitive air filter manufacturing industry, efficiency, consistency, and sustainability are crucial. Achieving strict quality standards while managing costs demands advanced, dependable machinery. Introducing the ECO Filter Heat Forming Machine—a professional solution designed to streamline the production of high-performance, eco-friendly air filter components through precise energy management.

What is the ECO Filter Heat Forming Machine?

This specialized industrial equipment is specifically engineered to produce buffer cores for environmentally friendly air filter cartridges. Its main function is to apply controlled heat and pressure within a mold cavity. Using precise electrical controls, operators can set the ideal temperatures for the machine’s upper and lower heating plates. Pre-cut buffer core materials—usually non-woven synthetic or blended filtration media—are placed inside the mold. The machine then closes, applies pressure, and heats the material simultaneously with the heating plates to thermally activate and permanently shape it according to the mold’s specifications. This process creates essential structural parts of air filters, ensuring an exact fit and consistent performance.

Unique Advantages: precision meets efficiency.

The ECO Filter Heat Forming Machine stands out by addressing key manufacturing challenges.

1. excellent energy efficiency and intelligent control

High-Efficiency Heating Elements: Minimizes energy waste during the heating phase, directly reducing operational costs.

Accurate PID temperature control: Intelligent system continuously monitors and adjusts the temperature of the upper and lower heating plates. This can ensure that the precise and stable temperature (1-2 C) required for perfect molding is maintained, and the undercooling or overheating leading to nonconforming products can be eliminated. Compared with the system with low degree of control, this precision directly translates to significant energy-saving effect.

2. Unparalleled user experience and simplicity

Intuitive Touchscreen Interface: Replacing complex knobs and dials, the user-friendly touchscreen allows operators to set and monitor all critical parameters (temperature, cycle time) with ease. This has greatly reduced the training time and minimizes the possibility of human error.

Simplify Operation: through digital interface, the parameters can be adjusted quickly and directly for different filter elements, thus improving the production flexibility.

3. Consistent, High-Quality Output:

The combination of accurate temperature control, uniform pressure application and solid mold design ensures that each filter element produced is exactly the same. This consistency is crucial for ensuring the final air filter meets stringent performance and sealing requirements.

4. Designed for Eco-Filter Production.

Specially designed for materials used in modern environmental protection air filters to ensure the best molding effect without reducing the performance of the filter media.

A powerful Specifications for reliable performance

Built for the demands of industrial production environments, the ECO Filter Heat Forming Machine

| Speed | 2pcs/min |

| Motor power | 3kw |

| Work air pressure | 0.65Mpa |

| Temp.of up plate | 175°C |

| Temp.of down plate | 155°C |

| Heater power | 8kw |

| Weight | 400Kg |

| Size | 800*600*1900mm |

Quality manufacture and assurance

The ECO Filter Heat Forming Machine is manufactured with a focus on durability and reliability:

ISO/CE certified Production: comply with international quality management and safety standards throughout the whole production process.

Robust Frame Construction: Built using high-strength steel to withstand constant pressure cycles.

Precision Machined Components: Critical parts like molds, plates, and guides are machined to tight tolerances, ensuring alignment and longevity.

High-quality core Components: the use of reputable gears, pumps and motors can ensure reliable operation and reduce the need for long-term maintenance.

Rigorous Testing: Machines undergo comprehensive functional and safety testing before shipment.

Targeted Application: Eco-Friendly Air Filter Production.

The primary and specialized application of this machine is clear-cut:

Forming the cushion core of air filter: It is a filter media cores specially designed for hot forming various types of air filters. These filter elements are essential components, providing filter surface area and structural integrity within the filter housing.

Eco-Friendly Focus: the machine is ideally suited for processing materials used in modern “eco-filter” designs, which often utilize synthetic or blended media designed for high efficiency, longer life, and reduced environmental impact compared to some traditional materials.

Ideal for Manufacturers Producing Filters For:

Automobile: engine room air filters, engine air intake filters.

HVAC system: air handling equipment for residential, commercial and industrial use.

Industrial machinery: air inlet filters for engines, compressors and turbines.

Household Appliances: air cleaner, vacuum cleaners.

Conclusion: The Smart Choice for Precision Filter Core Production

The ECO Filter Heat Forming Machine is more than just a forming press; This is a technologically advanced solution, aiming at improving the manufacturing of air filters. By combining high-efficiency heating, intelligent temperature control and very humanized touch screen operation, it brings tangible benefits: reduced energy consumption, minimized waste caused by rejection, reducing the training cost of operators, and most importantly, consistently improving the filter element.

This machine represents a major step forward for manufacturers who are committed to producing high-quality and environmentally-friendly air filters efficiently and reliably. Its robust construction, adherence to ISO/CE standards, and focused design make it a valuable asset on the production floor.