In the complex automobile system, the fuel filter plays an important role as a “scavenger”. It can effectively filter impurities and moisture in the fuel, protect the precise engine fuel injection system from damage, ensure efficient and stable operation of the engine, and reduce tail gas emissions. The core equipment for manufacturing this key component is the fuel filter coiling machine. This special machine combined with advanced technology is the basis for efficient and stable production of modern filters.

Automation experts in precision manufacturing

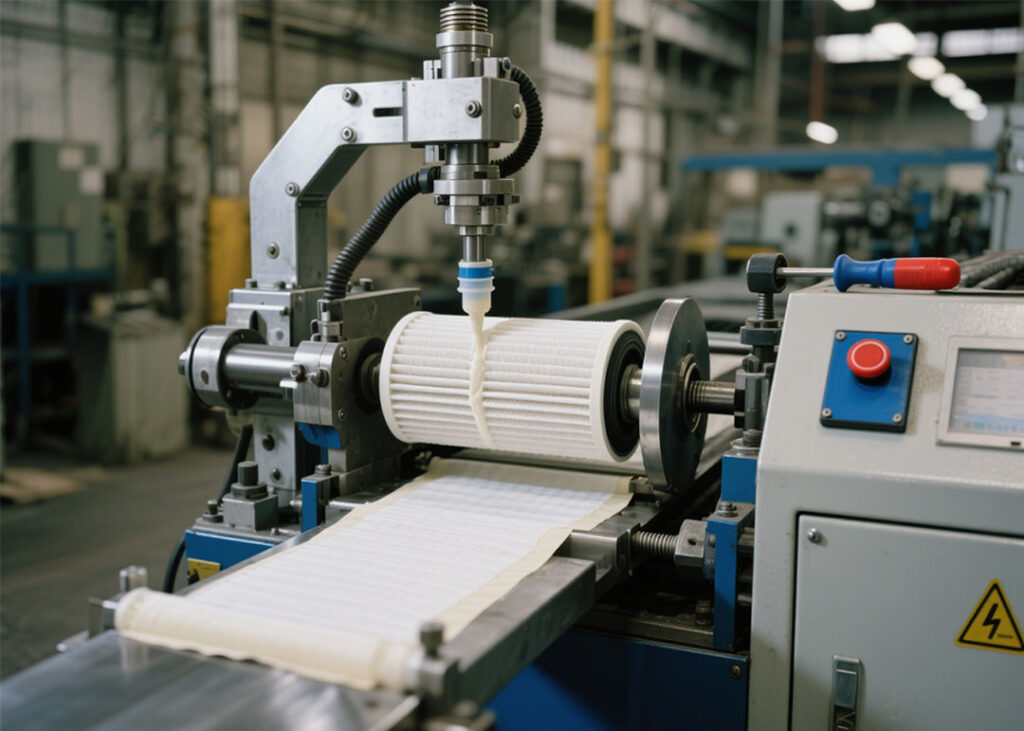

As the name implies, the fuel filter coiling machine is an automatic machine that specializes in producing the fuel filter core. It will be a specific filter material (usually specially treated filter paper) and an adhesive (such as. Hot melt adhesive), and through a series of precise processes, it is wound into a cylindrical filter cartridge with a specific filtering precision and structural strength.

The core working principle is clearly divided into four steps with high synergy:

1. Corrugation: This is the first step to endow filter paper with key structure. This is the first step in giving the filter paper its key structure. The machine sends flat filter paper into a precision pleating device. The unique heating and temperature control device is a remarkable advantage of the machine. By accurately heating and controlling the temperature of the pleating area, the paper can form a more uniform pleat pattern (pleat) more quickly and consistently. This not only improves efficiency, but also ensures the good circulation area and structural strength of the final filter element.

2. Gluing: the pleat-formed filter paper enters the gluing station. The machine precisely applies the adhesive (usually hot melt) to the specific position of the filter paper. Uniform and proper adhesive is the key to ensuring that the filter paper layers are firmly adhered to each other and the filter cartridge is not layered.

3. Lamination: Depending on the design of the box, it may be necessary to accurately laminate multiple layers of different materials (e.g. Filter paper and support net) are combined together. The station ensures that the layers are precisely aligned and ready for winding.

4. Winding and cutting: This is the core step in forming the final ink cartridge shape. The glued and laminated filter material is precisely wound on the central skeleton (usually a metal or plastic end cover assembly). When the winding length reaches a preset value, the machine will automatically carry out pneumatic cutting with high speed and high precision. Then pneumatic winding is completed, and the formed cartridge is automatically and smoothly transferred to the next process (for example. G. Curing, shell assembly, etc.) by Pneumatic Unloading.

Core Advantage: stability, high efficiency, and easy operation

The reason why the fuel filter coiling machine becomes the industry standard equipment is because of a series of unique advantages:

1. Precision Machining & Stability: the core parts of the equipment are manufactured by precision machining to ensure high stability and consistency in long-term operation. This is the fundamental guarantee for improving production efficiency and ensure product quality (for example. Filtering accuracy, bursting pressure). Stable operation means less down time and higher output.

2. Touchscreen Control & User-Friendly: Modern fuel cartridge winders are generally equipped with an intuitive touchscreen control system. The operation interface is user-friendly, and the parameter settings (such as winding length, speed, temperature, etc.) are clear at a glance and easy to adjust. This greatly reduces the technical threshold of the operator and improves the flexibility of production scheduling.

3. Heating and temperature control: As mentioned above, compared with the traditional method without heating, the integrated heating and temperature control system significantly speeds up the folding forming process of the filter paper, which is one of the key technologies for the high productivity of the machine.

4. Pneumatic Automation: pneumatic operation is adopted for cutting, winding and discharging, which is fast, accurate and reliable, perfectly replacing the tedious manual operation, and ensuring the consistency of the production rhythm and product.

Key specification parameters: the quantitative expression of performance.

Knowing the specification and parameters of the equipment is the key to evaluating its applicability. The following are the core parameters of the fuel filter winder:

1. Working Width: 30 mm – determines the maximum width of filter media that can be processed and is suitable for common small to medium sized fuel filter elements.

2. Speed: 1-6 meters/minute-adjustable linear speed, allowing the capacity to be optimized according to the complexity and material characteristics of the cartridge.

3. Total Power: 9.1 kW-the total electric energy consumption required to run the machine.

4. Operating air Pressure: 0.6 MPa (approximately. 6 bar) – the standard compressed air pressure required to drive the pneumatic elements.

5. Voltage: 380 v (three-phase) – the industry standard power supply requirement.

6. Applicable Materials (Applicable Materials): Hot Melt – Specify the core raw materials for the equipment.

7. Place of Origin: Hebei, China – Manufacturing origin.

8. Warranty: 1 year – the standard quality assurance period provided by the manufacturer.

9. Packaging Details: the equipment is first wrapped in shrink wrap for protection and then packed in a sturdy wooden case to ensure safe transportation.

Wide range of application scenarios: the core of automotive aftermarket and manufacturing industry

- Fuel filter manufacturers: this is the core application of this equipment. Whether it is to provide support for OEM (original equipment manufacturer) or to provide services for the vast automobile after-sales market (replacing filter), filter manufacturers rely on this equipment to manufacture the core of the fuel filter element efficiently and in batches.

- Auto Parts Industry Chain: As the core production equipment of fuel filter, a key component of the automobile engine system, it is an indispensable link in the auto parts manufacturing industry chain.

- Manufacturers specializing in fluid filtration: Although it is mainly designed for fuel filter elements, its complicated winding and bonding technology principle provide production possibilities for other precision fluid filter components that need similar processes, provided that the materials are suitable.

The Fuel Filter Element Winding Machine is not a simple paper winding machine, it is a professional manufacturing equipment that combines precision machinery, automation control, material handling (pleating, gluing) and thermal technology. Its stable operating performance, efficient heating and molding capability, convenient touch screen operation and automated pneumatic process together ensure that the fuel cartridge, a key automotive component, can be produced in large scale, high quality and high efficiency. With the continuous growth of global car ownership and the increasingly stringent environmental regulations, the demand for high-performance fuel filters is also growing. Choosing a winding machine with reliable performance and advanced technology is very important for filter manufacturers to enhance their core competitiveness, ensure the stability of supply chain and meet the market demand.