Key Takeaways

In the field of industrial filtration manufacturing and metal mesh manufacturing, the demand for high precision and high efficiency processing equipment is increasing exponentially. As core components of air and liquid filtration systems, metal mesh products need to be strictly controlled in cutting accuracy and edge quality to ensure their filtration performance. Among various processing equipment, the Slitting Machine plays a pivotal role, especially the Punch Press V-Type Slitting Machine designed specifically for metal mesh processing. This paper will comprehensively discuss how this specialized cutting machine can realize high-quality metal mesh processing, its unique advantages, product specifications, application scenarios and related professional knowledge, and provide valuable references for industry practitioners. At the same time, we will introduce a reliable supplier of slitting machine to provide this kind of high-performance equipment.

1. What is The Punch Press V-Type Slitting Machine?

The Punch Press V-Type Slitting Machine is specialized industrial equipment for precision slitting and punching of metal mesh and filter frame components. Integrated stamping and cutting functions are tailored for the needs of industrial filtration manufacturing. Its core design relies on a V-type punch structure to achieve stable, precise metal mesh processing, ensuring consistent cutting quality and uniform output, serving as a key component in modern metal mesh production lines to enhance efficiency and product quality.

2. unique Advantages

Compared with traditional slitting machine, this equipment has obvious advantages, which are mainly embodied in the following aspects.

2.1 v-Type Punch Design Ensures Stable Performance

The V-shaped pressing structure, the core advantage, boosts rigidity and strength, maintaining stable cutting performance even under heavy loads. It effectively reduces operational vibration (a major factor affecting precision in high-volume production). Industrial tests show that compared with the traditional rectangular structure, it reduces the running vibration by more than 30% and greatly improves the machining stability.

2.2 precision cutting and punching capability

Accuracy is very important for metal mesh processing, especially filter meshes needs strict grid size and edge smoothness control. The machine achieves precise cutting and punching of metal mesh and filter frame components, with tolerances meeting industrial filter standards. This ensures uniform mesh size and smooth edges, and avoids uneven filtering performance caused by inaccurate treatment.

2.3 automatic feeding improves production efficiency

It is equipped with an automatic feeding device, which reduces manual intervention and keeps a consistent production processes. Manual feeding is inefficient and prone to position errors that affect accuracy, while automatic feeding can run continuously and stably, speeding up the production pace.

2.4 industrial-Grade Construction Ensures Long-Term Reliability

Adopting industrial-grade structural materials, it features a sturdy frame and components for continuous operation with minimal maintenance. Its industrial steel frame has strong load-bearing capacity and corrosion resistance, and can adapt to harsh workshop environment (such as. High humidity and high temperature fluctuations). The minimum maintenance design reduces downtime and further improves the efficiency of the production line.

2.5 efficient workflow reduces downtime

The optimized press and blade arrangements of the Punch Press V-Type Slitting Machine effectively reduce downtime and increase production throughput. In the design process of the equipment, the continuity of the processing flow is fully considered, and the time required for replacing the blade and adjusting the parameters is reduced to the maximum extent. The quick tool change design allows operators to complete blade change in a short time, while the optimized parameter setting system realizes the quick switch between different processing tasks, which adapts to the production requirements of multi-type and small-batch metal mesh products.

3. Product Specifications of Punch Press V-Type Slitting Machine

The following table details the technical specifications of the Punch Press V-Type Slitting Machine, providing accurate parameter references for users to select equipment.

| Functional | description |

| Machine Type | V-type punch press slitting machine |

| Applicable Material | Metal mesh, steel wire mesh |

| Cutting Method | Punching & Slitting |

| Automation | Semi-automatic material feed |

| Power Source | Electric motor driven |

| Structural Material | Industrial steel frame |

| Guarantee | 1 year |

| Originated | China |

4. The main application scenario

The Punch Press V-Type Slitting Machine, with its excellent performance and precision processing capability, is widely used in various metal mesh processing fields. The main application scenarios include.

4.1 metal Mesh Slitting and Cutting

Suitable for cutting all kinds of metal mesh and wire meshes, including plain mesh, twill mesh and corrugated mesh. When producing metal mesh products of different specifications, the equipment can accurately cut according to the required width and length, thus ensuring the dimensional accuracy of the finished product. This situation is widely used in the production of building nets, decorative nets and industrial filter.

4.2 filter Frame Component Preprocessing

Filter frame assembly is an important parts of filtering equipment, and its machining accuracy directly affects the sealing performance and filtering effect of the filter. The Punch Press V-Type Slitting Machine can perform precision punching and slitting on filter frame components, completing preprocessing tasks such as cutting the frame material and punching installation holes. This kind of application scenario is common in the production of air filters, water filters and oil filters.

4.3 industrial Mesh Structure Fabrication

The equipment provides accurate processing support in the manufacture of industrial mesh structures such as mesh platforms, mesh fences and mesh baskets. It can process metal mesh materials into various shapes and sizes required by the mesh structure, ensuring the stability and load-bearing capacity of the structure. This scene is widely used in industrial workshops, construction sites, transportation fields.

4.4 support grid trimming for air and liquid filters

Support net is an important part in air and liquid filters, which supports the filter medium and ensuring the smooth flow of the filtered fluid. The Punch Press V-Type Slitting Machine can trim the support mesh to the required size and shape, ensuring that it fits perfectly with the filter body. According to the requirements of industrial filtration, the accuracy of the supporting net directly affects the filtration efficiency. The data show that the precision of the supporting net processed by professional cutting machine can improve the overall filtration efficiency of the filter by 15% -25% (Source: http://m.toutiao.com/group/7586949998802207283/?upstream_biz=doubao).

5. Operation Steps of Punch Press V-Type Slitting Machine

In order to ensure the processing quality and safety of the equipment, the correct operation steps must be followed. The standard operation steps of the Punch Press V-Type Slitting Machine are as follows.

1. Material Preparation: according to the processing requirements, select the appropriate metal mesh or steel mesh, check the quality of the material to ensure that there are no defects such as cracks, deformation and impurities. According to the processing plan, the material is cut into appropriate lengths to facilitate feeding.

2. Equipment debugging: Turn on the power supply of the slitting machine, start the preheating procedure of the equipment, and check whether all component (such as the punch, slitting blade and feeding mechanism) are working normally. According to the machining requirements, adjust the punching and slitting parameters, including cutting width, punching position and feeding speed.

3. Feeding setting: Put the prepared material on the feeding platform and adjust the positioning device to ensure that the material are consistent with the feeding direction. Start the semi-automatic feeding mechanism, try to feed, and confirm that the feeding position is accurate and the feeding speed is steady.

Formal processing: Start the formal processing procedure after confirming that the equipment and materials are normal. According to the set parameters, the equipment will automatically complete the punching and cutting tasks.

4. In the process of processing: the operator should closely monitor the operation of the equipment and the quality of the processed products, found abnormal situation should be stopped in time.

5. Finished product Inspection: After the processing is completed, take out the finished product and check its size, edge quality and punching precision. For nonconforming products, analyze the causes and adjust the equipment parameters. Qualified products are classified and stored according to the requirements.

6. Equipment downtime maintenance: After the processing task is completed, turn off the power supply of the equipment, clean the equipment, and remove the surplus material and sundries on the machine. Check the wear condition of vulnerable parts such as blades, and replace or repair them if necessary to ensure the long-term stable operation of the equipment.

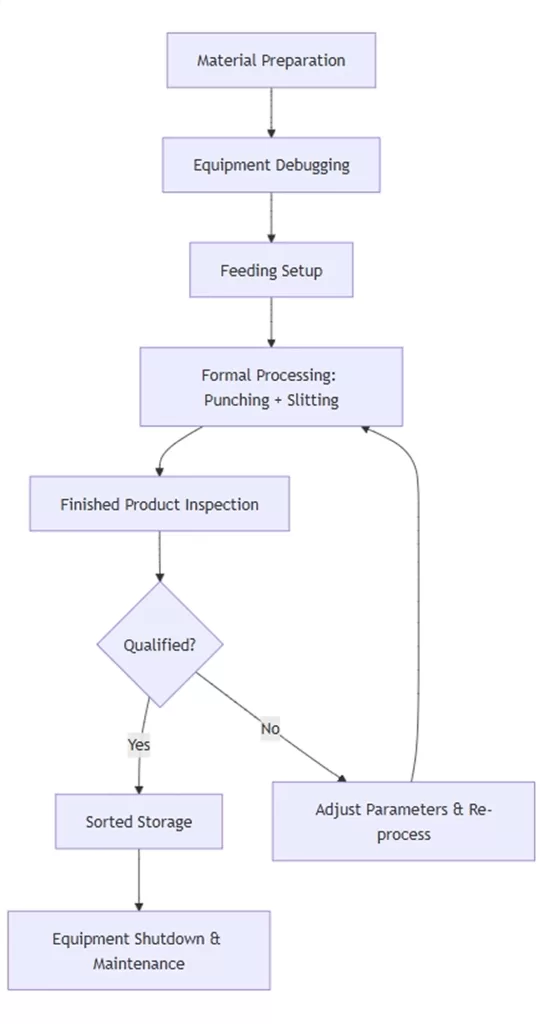

6. Workflow Diagram of Punch Press V-Type Slitting Machine

The following is the workflow diagram of the Punch Press V-Type Slitting Machine, which intuitively shows the entire processing process from material input to finished product output.

7. Frequently asked questions (FAQ)

Q 1: What materials can this Punch Press V-Type Slitting Machine process?

A: It is specially designed for processing metal mesh, wire mesh, and materials related to filter frame. It is especially suitable for all kinds of industrial grade metal mesh materials, such as steel mesh, stainless steel mesh and copper wire mesh.

Q 2: How does the V-type design help the machine?

A: The V-type structure improves the rigidity and strength of the machine. Compared with the traditional structure, it can effectively reduce the vibration during the operation, thus improving the cutting accuracy and ensuring the stability of machining performance under heavy load.

Q 3: Is this Slitting Machine suitable for high-volume production?

A: Yes. The machine’s solid industrial structure and semi-automatic feeding mechanism support continuous industrial operations. The optimized workflow reduces downtime, which can meet the needs of high-volume production lines. It is an ideal choice for large-scale wire screen processing enterprises.

Q 4: How long is the warranty period of this equipment?

A: the warranty period of this Punch Press V-Type Slitting Machine is 1 year. During the warranty period, the supplier of the slitting machine will provide free maintenance and replacement of faulty parts (excluding man-made damage)

Q 5: Do I need professional training to operate this kind of equipment?

Answer: Although the operation of the equipment is simple, it is recommended that operators receive professional training before operation. The supplier will provide detailed operation manuals and on-site training services to ensure that operators can master the correct operation methods and safety precautions.

8. Why Choose Our Punch Press V-Type Slitting Machine?

As a professional supplier of slitting machines, we are committed to providing high-quality and high-precision slitting machines to industrial customers. Our Punch Press V-Type Slitting Machine has won the trust of customers with its excellent performance and reliable quality. We chose our equipment for the following reasons.

- Professional Design: the structure of V-type punching machine is specially designed for metal mesh processing, which accurately meets the requirements of industrial filtration manufacturing.

- Stable performance: industrial-grade structural materials and optimized component design ensure long-term stable operation of the equipment with minimum maintenance.

- Precision machining: Accurate punching and cutting capability ensure the quality consistency of the processed products and improve the competitiveness of customers’ products.

- Efficient Production: the semi-automatic feeding mechanism and optimized workflow improve production efficiency and reduce production costs.

- Perfect after-sales service: We provide one-year warranty, on-site installation and debugging, and professional training services to solve customers’ worries during use.

In conclusion, the Punch Press V-Type Slitting Machine is an indispensable key piece of equipment in the field of metal mesh processing. It can effectively improve the machining accuracy and efficiency, and help enterprises to reduce costs and increase efficiency. If you are looking for a reliable Slitting Machine for metal mesh processing, please contact us. As a professional supplier of slitting machines, we will provide you with customized solutions and high-quality equipment and services.