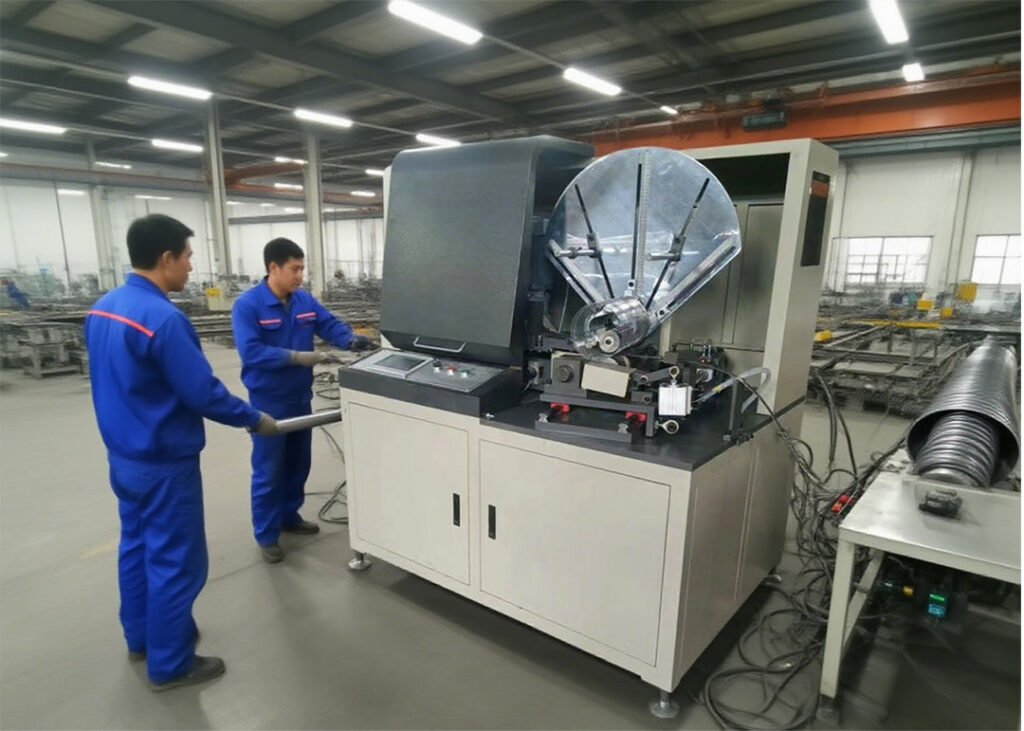

The Expanded Metal Spiral Tube Making Machine 109 mm is precision-engineered equipment dedicated to manufacturing structural mesh cylinders for industrial filtration systems. The machine is specially designed for 109 wide steel strips (0.4-0.7mm thick), and the flat metal plate is transformed into spiral support tube through an integrated five-stage process. These components serve as critical inner/outer cages for air filters ranging from 90 mm to 420 mm in diameter – essential elements in HVAC, industrial dust collection, and power generation applications.

Precise manufacturing technology

This machine integrates five synchronous operations into one continuous workflow:

1. Steel Belt Feeding: Coiled metal strips are automatically fed into the system.

2.Diamond Perforation: Precision punching creates uniform diamond-shaped openings.

3.Edge Expansion: the mechanical flanges forms interlocking edges along both sides.

4.Seam Formation: Hook-shaped edges prepare for seamless connection.

5.Spiral Rolling & Cutting: Programmable rails coil metal into cylindrical forms and cut to length.

This comprehensive method realizes the continuous production of 10, while maintaining the dimensional tolerances of 0.2mm, eliminating traditional welding requirements.

Scientific and technological superiority

The Expanded Metal Spiral Tube Making Machine incorporates unique 109 mm width optimization technology, bringing clear industrial benefits:

· Material Efficiency: the utilization rate reaches 98% by eliminating finishing waste.

· Production Simplification: replacing 5+traditional traditional stages with single-step molding.

· Precision engineering: the expansion of guide rail ensures the consistency of geometry.

· Operation flexibility: the conversion between diameters (90-420mm) can be completed within 15.

· Quality Consistency: Automatic weld inspection ensures the integrity of the structure.

Key norms

The machine is powered by standard 380 v industrial power supply, and the air pressure is required to be 0.6 MPa. It has a compact size of 1600 1100 1400 mm and a stable structure of 1200 kg. Its 3 kW motor drives continuous production at a speed of 10 when dealing with carbon steel/galvanized steel (0.4-0.7mm). SJ PLC control system with touch screen interface can realize accurate parameter adjustments, supplemented by comprehensive safety systems, including emergency stop and overload protection.

Industrial Applications program

The Expanded Metal Spiral Tube Making Machine 109mm plays a vital role in:

· Manufacturing of HVAC: producing 200-420mm structural cores for commercial air processors.

· Industrial filtration: manufacturing heavy-duty filter cages for the factory.

· Energy Sector: manufacturing reinforced casings for turbine intake filters.

· Automobile: Provide precise network management for cabin air filtration systems.

Operational advantages

This machine has brought about significant production advantages.

Compared with the manual manufacturing method, the yield is increased by 83%.

· Zero welding requirements for corrosion-resistant structures.

· Integrated quality control using material defect detection sensors.

· Low-maintenance design with self-lubricating bearings (10,000+ hours lifespan).

· Energy efficiency is about $ 0.48/hour operation cost.

Third-party test confirmed that the maximum radial deviation was 0.02 mm after 500 cycles, and the compressive strength was 25% higher than that of welding substitutes. Under the operation of two shifts, most manufacturers get a return on investment within 6-8 months.

Technical verification

The recorded performances include:

· Consistent diamond-shaped perforation geometry (1.5 0.1 mm apex angles.

· ± 0.15 mm radial tolerance maintained through SJ PLC-controlled tension.

· Production capacity is 50+ filter elements per hour.

· Mechanical/electrical components are guaranteed for 12 months.

Conclusion: the engineering precision of modern manufacturing industry is precise.

The Expanded Metal Spiral Tube Making Machine 109 mm represents a technological leap in filter component production. As confirmed by industry adopters: “Our mesh tube production costs decreased by 37% while eliminating dimensional rejections” (Tianjin Filter Tech). By combining material efficiency, precision engineering and fast conversion ability, this ISO 9001 certified equipment (made in Hebei, China) provides real improvements in quality consistency and production economy for global industrial filter manufacturers.