Unveiling the Source of High-Performance Power—High-Flow Air Filter Production Line

What is a High-Flow Air Filter?

In the worlds of modified cars, racing, and high-performance motorcycles, the term “high-flow air filter” is a familiar one. It promises smoother airflow, more efficient combustion, and stronger power output. But have you ever wondered how that seemingly simple pleated filter media is precisely manufactured? Today, we’ll go behind the scenes to explore the core equipment used to create this “source of power” – the pleating machine, slitting machine, cross-cutting machine, and the automated production line they form.

I. Core Mission: Why Specialized Equipment is Needed

Unlike conventional filters, the core of a high-flow filter lies in its enormous effective filtration area. This is achieved through an extremely precise and uniform pleated structure. Within the same volume, the more uniform the pleats, the greater the filtration area and the lower the intake resistance.

Handcrafting simply cannot achieve this level of precision and efficiency. Therefore, a highly specialized automated production line is the only way to manufacture qualified, high-performance filters. These systems ensure consistent performance across every product.

II. The Three Core Machines of the Production Line

An efficient production line typically consists of the following three core machines working in sequence:

1. Pleating Machine – The “Heart” of the Production Line

· Function: This is the core of the entire process. Typically, filter media is sandwiched between two layers of mesh and precisely folded by the machine into continuous, uniform waves (pleats).

· Pleating Precision: Controlled by precise gears, cams, or servo systems to ensure every pleat has consistent wave height and pitch. This is the key parameter determining filtration area and flow rate.

· Adjustability: Unlike traditional pleating machines, CNC pleating machines allow operators to simply enter the desired height and pleating speed on a display to produce filters with different pleat heights, eliminating manual adjustments.

· Adaptability: Capable of processing various types of filter media and metal meshes.

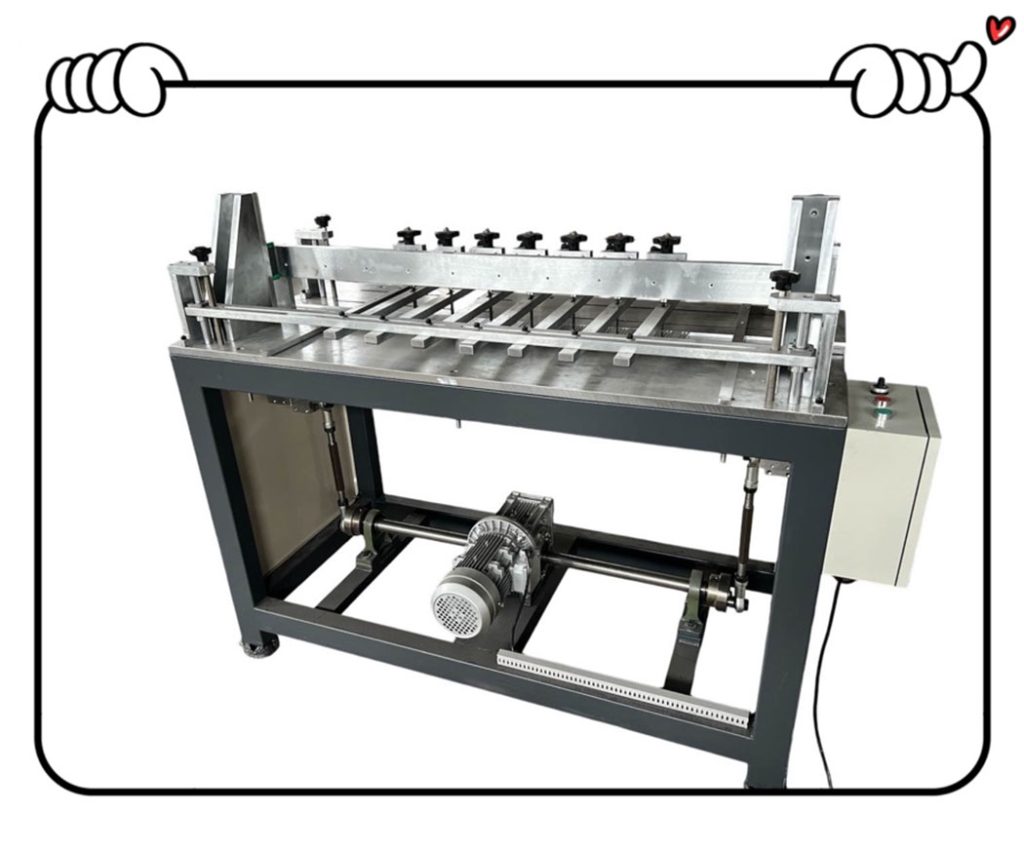

2. Slitting Machine – The “Planner” of Production

· Function: It slits the wide, pleated raw material into multiple narrow rolls based on the required height (or length) of the final product.

· Why It Matters: Precise slitting is the foundation of product formation. Inconsistent slit widths can result in uneven pleat heights, compromising quality.

· Key Features: Utilizes high-precision circular blades for clean slitting, with tension control systems ensuring the material does not stretch or deform during the process.

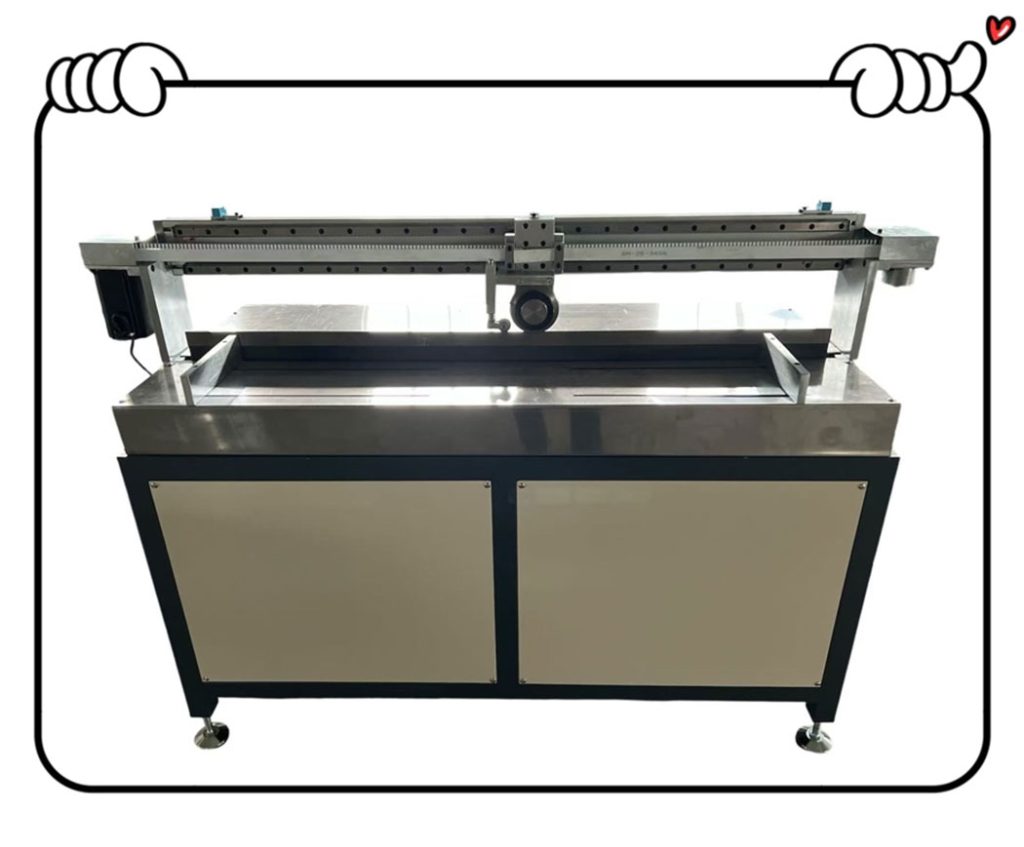

3. Cross-Cutting Machine – The “Finisher” of Shaping

· Function: It precisely cuts the continuous pleated material to a preset circumference (the length of one loop of the filter).

· Why It Matters: The cut length determines the diameter when the filter is coiled into a circle. Accurate cutting ensures proper fit during downstream assembly, avoiding gaps or overlaps.

· Key Features: Typically employs servo motor-driven high-precision blades (e.g., rotary cutters, guillotine blades) synchronized with the output speed of the pleating machine for length-based cutting, producing clean, burr-free cuts.

III. From Standalone to Supreme: Automated Production Line Integration

Modern high-efficiency manufacturing relies not on individual machines working in isolation but on their integration into a fully automated production line.

Workflow:

1. Unwinding: Raw material from large rolls is fed into the line.

2. Pleating (Core Step): The filter media is precisely pleated.

3. Slitting: The wide pleated material is slit into multiple narrow strips.

4. Cross-Cutting: The continuous pleated material is cut to length.

Advantages of Line Integration:

· High Efficiency: From raw materials to finished filter segments, the process minimizes human intervention and ensures extremely high production speed.

· High Consistency: Automation eliminates human error, ensuring every product is a high-standard replica.

· Low Cost and Low Waste: Reduced labor requirements and precise control minimize material waste.

IV. Considerations When Choosing Equipment

If you are a manufacturer planning to procure equipment, focus on the following:

· Filter Specifications: Clearly define key parameters such as wave height, wave pitch, circumference, and material type for the filters you intend to produce.

· Production Speed: Evaluate your expected output requirements (meters/minute or pieces/hour).

· Automation Level: Decide between manually operated standalone machines, semi-automatic lines, or fully automated integrated production lines.

· Equipment Precision and Stability: A core metric directly impacting product yield.

· Supplier Experience and After-Sales Service: Choosing a supplier with proven experience and reliable technical support is crucial.

Though small in size, the high-flow air filter embodies precise mechanical design, automation control, and materials science. The golden trio of the pleating machine, slitting machine, and cross-cutting machine forms the foundation that transforms innovative design into powerful performance. Working silently in factories, they are the starting point unleashing every extra unit of horsepower.

Type Feeding , CNC Folding ,and Longitudinal cutting Production Line

Share:

Categories

- blog(46)

- Industry news(3)

- Technique articles(43)

Recent Posts

What is the melt filter trimming machine ...

11/20/2025 Comments Off on What is the melt filter trimming machine and how does it enhance the filtration system?

What is a Melt Filter Shrinking Machine ...

11/18/2025 Comments Off on What is a Melt Filter Shrinking Machine and Why is it Essential for Filter Manufacturing?

What is a melt filter extruder and ...

11/13/2025 Comments Off on What is a melt filter extruder and how does it enhance your filtration system?